Every educator knows the frustration of watching carefully crafted classroom materials deteriorate after just weeks of use. However, advanced lamination techniques can transform your teacher poster maker preservation strategy, extending the life of educational resources by an impressive 300%. This comprehensive guide explores cutting-edge preservation methods that protect your investment in visual learning materials while saving significant budget dollars over time.

Understanding Modern Teacher Poster Maker Preservation

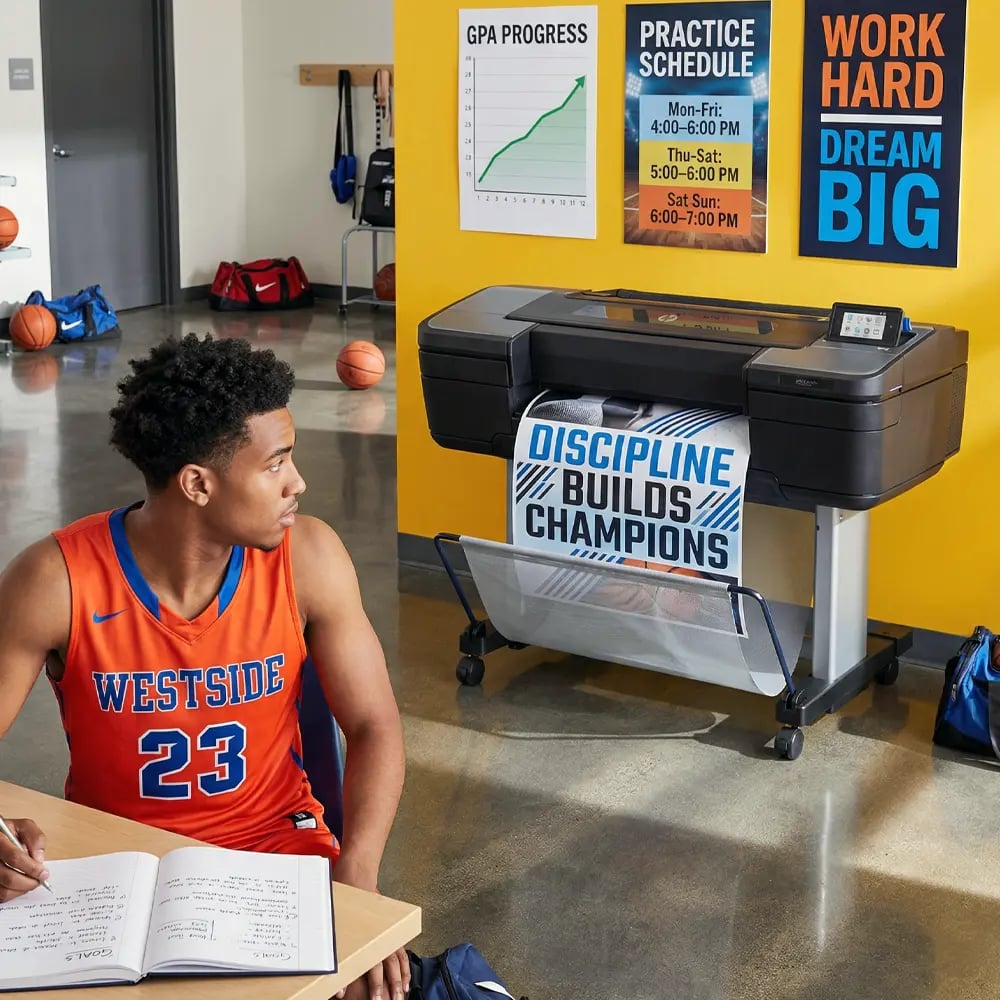

The evolution of preservation technology has transformed how schools protect their educational materials. Modern lamination goes beyond simple plastic coating to incorporate advanced features like UV protection, antimicrobial surfaces, and edge-sealing technologies. These innovations are particularly crucial for materials created with a school poster printer, where vibrant colors and sharp details need protection from daily classroom wear.

Research from the National Education Association indicates that properly laminated educational materials can withstand over 1,000 handling events compared to just 50-100 for unprotected papers. This dramatic improvement in durability translates directly to cost savings and reduced teacher preparation time.

The Science Behind Lamination Success

Lamination effectiveness depends on understanding the interaction between heat, pressure, and material composition. Different poster papers require specific temperature settings to achieve optimal adhesion without compromising print quality. For instance, materials from Coated Poster Paper respond best to temperatures between 250-275°F, while standard poster stock performs optimally at 290-310°F.

The molecular structure of lamination film creates a barrier that prevents moisture penetration, UV damage, and physical wear. Premium lamination films incorporate multiple layers, each serving a specific protective function. The outer layer provides scratch resistance, middle layers offer UV filtration, and the adhesive layer bonds permanently to the paper substrate.

Lifespan Increase

Materials protected with advanced lamination techniques last 3x longer than unprotected posters, saving schools thousands annually.

Teacher Poster Maker Preservation: Heat Settings Guide

Achieving professional-quality lamination requires precise temperature control based on material type. The following temperature guidelines ensure optimal adhesion without damaging your poster prints:

Advanced Edge-Sealing Techniques

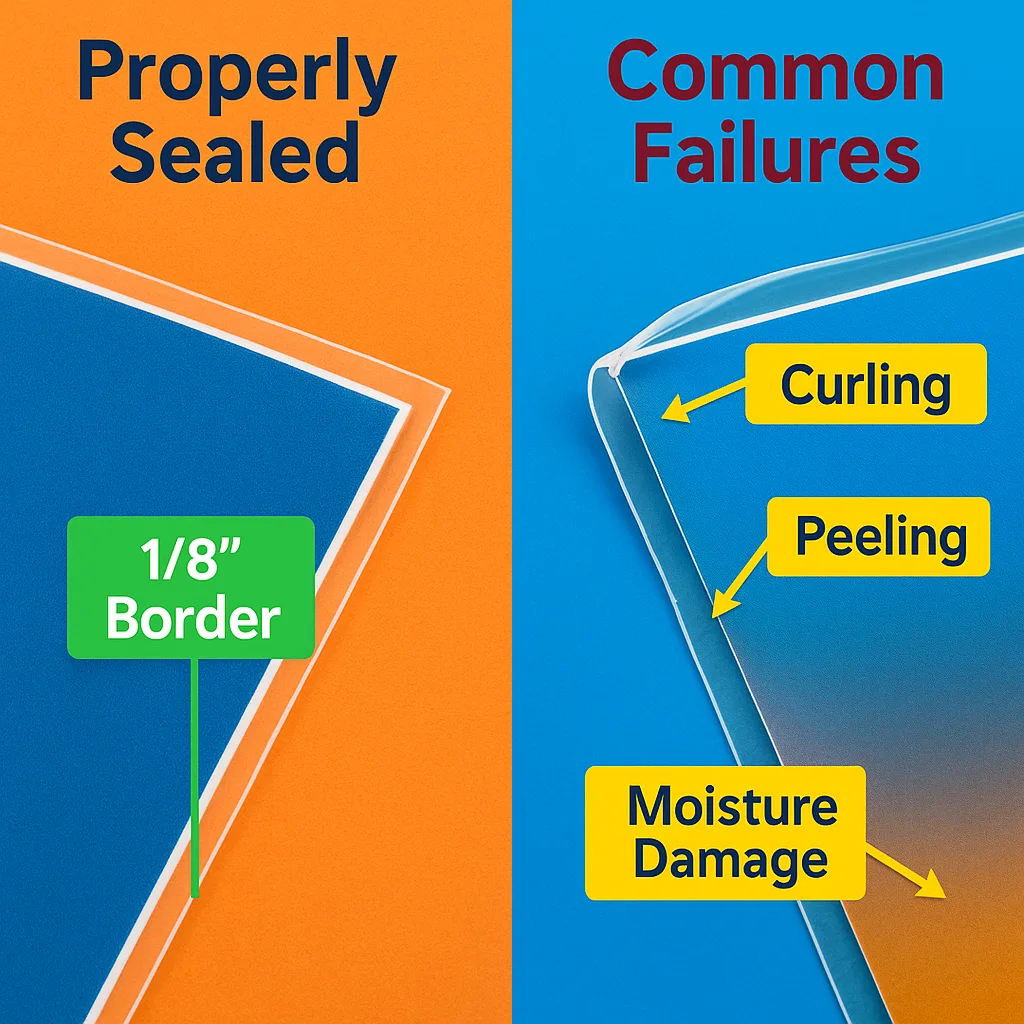

Edge sealing represents the difference between amateur and professional lamination results. Proper edge treatment prevents moisture infiltration, edge peeling, and premature failure of laminated materials. Professional educators using a teacher poster maker system need to understand these critical techniques to maximize material longevity.

The most effective edge-sealing method involves creating a minimum 1/8-inch border of lamination film around all edges. This buffer zone should be trimmed with a rotary cutter rather than scissors to prevent micro-tears that can initiate delamination. For high-touch materials like alphabet charts or number lines, consider double-laminating with offset edges for enhanced durability.

Heat Sealing

Professional Results

Run a heat sealer along edges at 180°F for permanent moisture barrier. Essential for bathroom passes and outdoor signage.Ultrasonic Welding

Industrial Strength

High-frequency vibrations create molecular bonds. Ideal for materials exposed to heavy handling or cleaning solutions.Chemical Bonding

Maximum Protection

Solvent-based edge treatments create waterproof seals. Perfect for science lab posters and cafeteria displays.Cost-Per-Year Investment Analysis

Understanding the true cost savings of proper lamination justifies equipment investments for schools using poster printing solutions.

Without Lamination: Replace materials every 2-3 months Average cost: $450/year per classroom

With Basic Lamination: Replace materials every 8-10 months Average cost: $180/year per classroom

With Advanced Preservation: Replace materials every 24-36 months Average cost: $75/year per classroom

UV Protection: The Hidden Destroyer

Ultraviolet radiation silently degrades educational materials, causing colors to fade and paper to become brittle. Classrooms with large windows experience accelerated deterioration, particularly affecting materials created with a school poster printer that uses dye-based inks. UV-protective lamination films block up to 98% of harmful radiation while maintaining optical clarity.

The latest UV-blocking technologies incorporate titanium dioxide nanoparticles that absorb and dissipate UV energy without yellowing over time. These advanced films cost approximately 15-20% more than standard lamination but extend material life by an additional 150% in high-light environments.

Troubleshooting Common Preservation Failures

Integrating Preservation with Poster Studio Express Solutions

Schools investing in comprehensive poster-making systems benefit from integrated preservation strategies. The Education Studio 24″ Poster Maker Package A+ produces water-resistant prints that require minimal lamination for indoor use, while the PSE Cool 25″ Cold Laminator provides heat-free preservation ideal for thermal-sensitive materials.

For schools seeking maximum versatility, combining a quality teacher poster maker with professional lamination equipment creates a complete in-house production facility. This integration allows educators to produce, protect, and preserve materials efficiently, reducing outsourcing costs by up to 90%.

Transform Your Classroom Materials Today

Ready to revolutionize your teacher poster maker preservation strategy? Contact Poster Studio Express at 866-788-7900 to explore integrated solutions that protect your educational investments.