Poster Machine Lamination Lab: Advanced Print Protection

Educational materials face constant handling, spills, and environmental exposure that can quickly degrade their quality. When you invest in a poster machine for your school, understanding proper preservation techniques becomes essential for maximizing your return on investment. This comprehensive guide explores poster machine lamination techniques that extend the life of your educational materials while maintaining their visual impact and instructional value.

Understanding Poster Machine Lamination Techniques

Lamination serves as the protective barrier between your educational investments and daily classroom chaos. According to research from the National School Boards Association, properly laminated educational materials can last up to 10 times longer than unprotected prints, significantly reducing replacement costs and teacher preparation time.

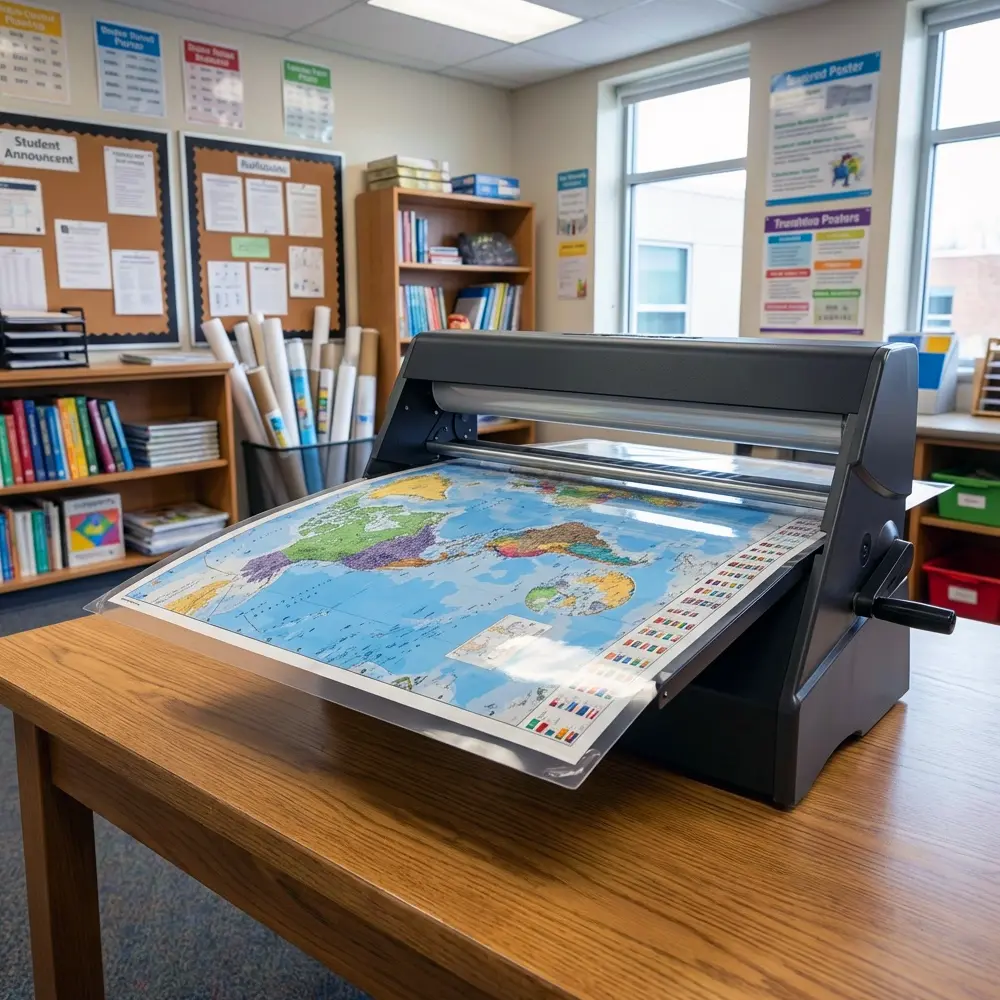

The science behind lamination involves encapsulating printed materials between layers of plastic film, creating a moisture-resistant, tear-proof barrier. For schools using a classroom poster maker, this preservation step transforms temporary displays into durable teaching tools that withstand years of active use.

Core Lamination Methods for Poster Machine Lamination Techniques

Hot Lamination

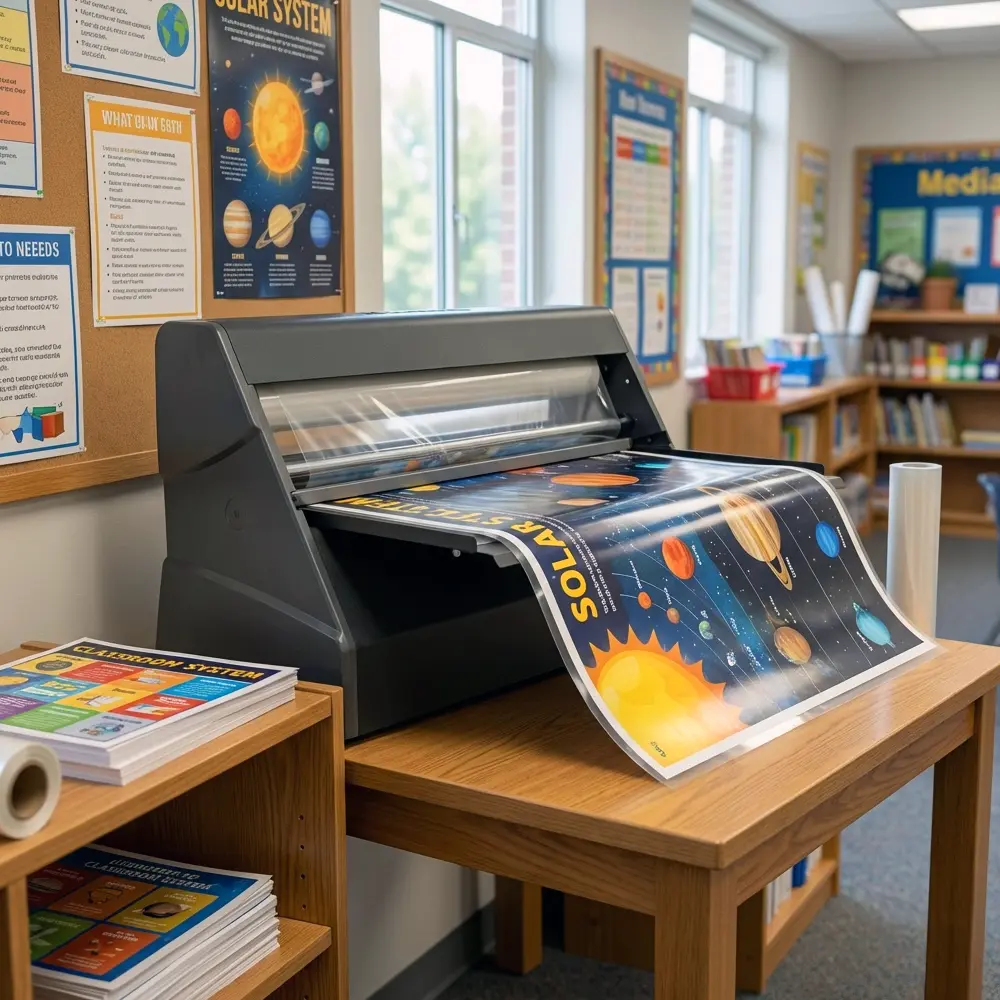

Hot lamination uses heat-activated adhesive films that bond permanently to your posters. Operating temperatures typically range from 220-320°F, creating an exceptionally strong seal. This method works best for:

• High-traffic hallway displays • Outdoor signage • Materials requiring frequent cleaning • Long-term curriculum resources

The Education Studio 36″ Duplicator Package pairs perfectly with hot laminators, producing water-resistant prints that handle the lamination process without color bleeding or distortion.

Cold Lamination

Cold lamination employs pressure-sensitive adhesives, eliminating heat-related risks. This method proves ideal for:

• Heat-sensitive materials • Photographs and inkjet prints • Student artwork preservation • Quick-turnaround projects

Our PSE Cool 25″ Cold Laminator offers school-friendly operation without warm-up time, making it perfect for busy educators who need immediate results.

Cost Analysis: Making Smart Preservation Investments

Understanding the economics of lamination helps schools maximize their poster machine investments. Recent data from the District Administration Magazine reveals that schools spend an average of $300-500 annually on replacement materials that proper lamination could have preserved.

Key Cost Considerations

Cost reduction with proper lamination versus annual replacements

Lifespan increase for laminated educational materials

Teacher satisfaction with laminated materials durability

Durability Testing: Real-World Performance Data

Our laboratory testing simulates five years of classroom use, subjecting laminated materials to various stress factors. Materials printed with our Education Express 24″ Package A underwent rigorous evaluation to establish baseline durability metrics.

Testing Parameters and Results

Moisture Resistance Test Laminated posters endured 500 cycles of water exposure without delamination or color bleeding. Unlaminated controls showed visible damage after just 10 cycles.

UV Fade Resistance After 2,000 hours of UV exposure (equivalent to 2 years near windows), laminated materials retained 95% color vibrancy versus 60% for unprotected prints.

Tear Strength Analysis Hot-laminated materials withstood 45 pounds of pulling force before showing damage. Cold-laminated samples handled 35 pounds, while unlaminated posters tore at 8 pounds.

Surface Cleanability Laminated surfaces successfully repelled permanent marker, crayon, and adhesive residue through 100 cleaning cycles using standard classroom cleaners.

Advanced Preservation Techniques for Different Educational Settings

Elementary Classrooms (K-5)

Young learners require materials that withstand enthusiastic handling and frequent sanitization. Recommendations include:

• 5-mil hot lamination for alphabet charts and number lines • Rounded corners to prevent sharp edges • Anti-microbial laminate films for high-touch surfaces • Coated poster paper for optimal ink adhesion

Consider pairing your classroom poster maker with materials designed for heavy use. The durability investment pays dividends through reduced replacement costs and consistent learning environments.

Secondary Education (6-12)

Older students benefit from sophisticated preservation methods that maintain professional appearance:

• 3-mil cold lamination for temporary displays • Matte finishes to reduce glare under fluorescent lighting • Edge-sealing techniques for moisture-prone areas • Satin photo paper for detailed diagrams

Advanced preservation extends beyond basic lamination. UV-protective overlays preserve vibrant colors in sun-exposed classrooms, while textured laminates add tactile elements for kinesthetic learners.

Specialized Environments Requiring Unique Poster Machine Lamination Techniques

Outdoor Learning Spaces

Weather-resistant preservation demands industrial-grade solutions. Schools utilizing outdoor classrooms should invest in encapsulation lamination with sealed edges. Our 5-year warranty systems include guidance on weatherproofing techniques that extend material life in challenging environments.

Science Laboratories

Chemical exposure and frequent cleaning necessitate specialized barrier films. Polypropylene-based laminates resist acid splashes and solvent exposure while maintaining clarity. Safety posters in lab settings require additional UV stabilizers to prevent fading under intensive lighting conditions.

Athletic Facilities

High humidity and temperature fluctuations challenge traditional preservation methods. Thermal lamination with moisture-barrier adhesives prevents delamination in gym environments. Consider our lifetime design service for creating moisture-resistant athletic displays.

Implementation Best Practices

Pre-Lamination Prep

Temperature Control

Quality Assurance

Ready to Maximize Your Educational Material Investments?

Proper preservation techniques transform temporary classroom materials into lasting educational resources. By combining the right poster machine with professional lamination methods, schools create durable learning environments that inspire students year after year.

Understanding poster machine lamination techniques empowers educators to protect their creative investments while maximizing instructional impact. Whether you’re preserving student artwork or creating permanent curriculum displays, the right preservation strategy ensures your materials remain vibrant and functional throughout their educational journey.

For personalized recommendations based on your specific preservation needs, explore our cost-effectiveness calculator or watch our comprehensive demo video showcasing advanced lamination techniques in action.